A vortex flowmeter is a flow measurement instrument designed based on the "Kármán vortex street" phenomenon. When fluid flows past a bluff body (vortex shedder) inside the pipeline, alternating rows of vortices are generated on both sides. By detecting the vortex frequency with a sensor and combining it with parameters such as pipe diameter and fluid density, the fluid velocity and volumetric flow rate can be accurately calculated.

As a cost-effective measurement instrument offering both high accuracy and wide applicability, vortex flow meters are widely used in industrial automation settings such as petrochemicals, energy, and water treatment. However, the measurand of vortex flowmeter is the volumetric flow rate under operating condition(working temperature and pressure). This value may not directly meet the requirements for process control in many practical applications:

Measurement of Gas and Steam: For compressible fluids—gas and steam—the density is highly sensitive to changes in temperature and pressure. An increase in pressure or decrease in temperature leads to a significant increase in density, where substantial deviations can be introduced due to changes in the actual density of the medium. For example, the same volumetric flow rate of natural gas under high pressure condition corresponds to a much greater mass than under low-pressure.

Special Conditions in Liquid Measurement: Although liquids are generally considered approximately incompressible, their volume still undergoes thermal expansion or compression under high temperature or pressure. For high-temperature and high-pressure liquids (temperature > 100°C or pressure > 10 MPa), volatile liquids (such as methanol, ethanol), or applications requiring high accuracy such as key process control aspects, neglecting the correction for the effect of temperature and pressure on liquid density will similarly introduce significant errors.

To address the issue, temperature and pressure compensation for vortex flowmeter is necessary. By measuring the fluid temperature and pressure in real time and incorporating the fluid's physical properties, the working condition volumetric flow rate measured by the vortex flow meter can be accurately converted to the required mass flow rate or standard volumetric flow rate.

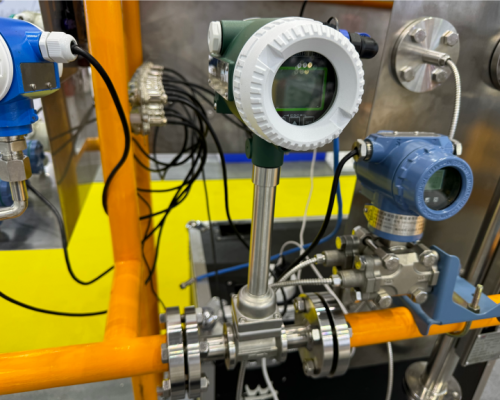

The traditional separate compensation approach involves equipping the vortex flowmeter with additional independent temperature sensor (e.g., platinum resistance thermometer) and pressure transmitter. The three signals are then fed into a flow totalizer or control system for calculation. This design often increases installation complexity and cost. Consequently, integrated temperature and pressure compensation technology has emerged as a development trend. It integrates high-precision temperature and pressure sensing elements with the vortex flow sensor into a single, compact measurement unit. Its core advantages include:

System Simplification and Reliability Enhancement: Reduces external wiring and quantity of independent instruments, lowering installation and maintenance costs and improving system immunity to interference and long-term stability.

Data Synchronization and Accuracy Assurance: Built-in sensors directly measure the actual temperature and pressure of the fluid near vortex shedder, enabling synchronized source-level acquisition of multiple parameters and avoiding compensation errors caused by measurement point discrepancies.

Function Integration and Intelligence: The integrated calculation module can utilize the acquired temperature and pressure values along with built-in medium density models (such as gas equation of state, steam tables, or liquid correction formulas) to perform online real-time calculation and output standard volumetric flow rate or mass flow rate, facilitating direct and convenient system integration.

Integrated temperature and pressure compensation represents a crucial functional enhancement for vortex flow meters to address changes in fluid properties with operating conditions and to achieve high-precision flow conversion, effectively supporting the needs of precise process control. Shanghai Wangyuan possesses over twenty years of professional experience in the field of instrument manufacturing and supply, offering a range of flow measurement products. Should you have any requirements regarding vortex flowmeters, we are pleased to provide solutions. Please feel free to contact us at any time.

Post time: Jan-26-2026