Pressure transmitters are essential measuring devices in the field of process control. In industrial automation settings, engineers typically need to monitor “zero drift” issues in pressure transmitters and perform zero calibration accordingly. Zero drift refers to the phenomenon where the measuring instrument's output signal gradually deviates from the theoretical zero point over time or due to environmental changes when the input is zero (no measured physical quantity is applied). For example, a pressure transmitter with a range of 0~10 MPa should ideally output 4 mA (for a 4~20 mA output) when exposed to atmospheric pressure (zero gauge pressure). Zero drift occurs when the actual output slowly and continuously deviates from this value. Systematic errors is directly introduced affecting measurement accuracy and control precision.

Why are Pressure Transmitters Prone to Zero Drift ?

Measurement Principle: Pressure transmitters typically operate based on the deformation of elastic element, involving physical transfer of pressure. This process can be influenced by factors such as installation position and medium characteristics, leading to deviation of zero point.

Usage Requirements: Pressure and differential pressure transmitters often need to adapt to different mounting positions and measurement conditions in industrial applications. For instance, when measuring the liquid level in a sealed tank, condensation of the gas phase medium may allow condensate to enter the impulse lines and the lower side of transmitter, causing measurement errors. In such cases, negative migration is required that shifts the transmitter's zero point to start from a negative differential pressure to meet operational needs.

Element Exposure: Pressure sensing components (such as isolation diaphragms) are in direct contact with the measured medium. Corrosion, scaling, particle impact or adhesion of viscous medium can alter their mechanical properties, resulting in zero point changes.

Environmental Factors: Uneven bolt tightening during installation, mechanical stress from pipeline thermal expansion and contraction or high static pressure (for DP transmitters) can cause deformation of pressure sensing diaphragm, introducing persistent static errors. Temperature fluctuation and on-site vibrations can also exert more complex effects.

How to Address Zero Drift in Pressure Transmitters?

Zero drift is a common issue in pressure transmitters and requires various technical measures to mitigate:

Factory Testing and Calibration: Conduct thorough high-low temperature and static pressure tests during production, storing compensation data in the transmitter for real-time correction.

Material and Process Optimization: Apply elastic materials with high fatigue strength and good temperature stability (Hastelloy, ceramic diaphragms, etc.) and optimize heat treatment processes to reduce internal stress.

Regular Maintenance and Calibration: Establish calibration cycles based on operating conditions and perform on-site calibration under zero conditions.

Improved Installation and Usage: Avoid over-tightening, use brackets to isolate pipeline stress and prevent medium solidification or crystallization.

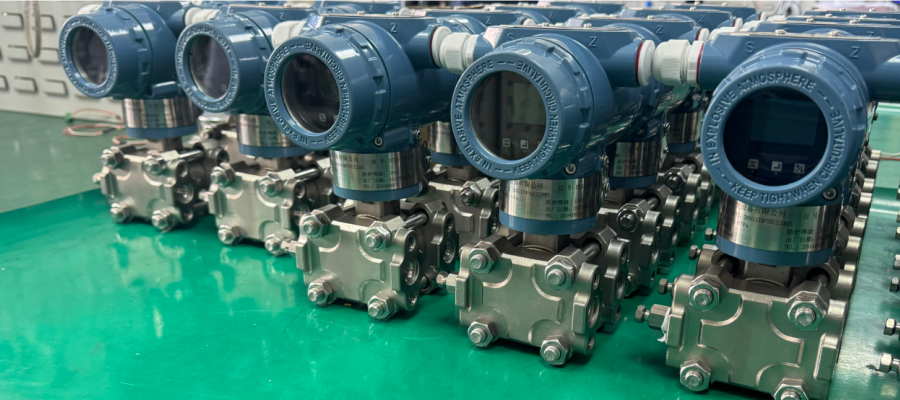

Shanghai Wangyuan is an instrument equipment manufacturer and supplier with over 20 years of experience. We have accumulated extensive on-site application practices and efficient troubleshooting expertise, enabling us to provide customers with stable and reliable products along with professional and timely technical support. If you have any questions regarding the selection or application of pressure and temperature transmitters, please feel free to contact us for solutions.

Post time: Jan-14-2026