In industrial processes such as power generation, chemical manufacturing, oil refining, and metallurgy, accurately measuring pressure in high-temperature environments can be a critical but challenging task. When the process medium temperature rises above 80℃, standard pressure transmitters could become vulnerable. Direct exposure to such heat may degrade electronic components, cause measurement drift, damage internal filling fluids, and ultimately lead to major instrument malfunction. Success in these demanding applications hinges on a holistic strategy encompassing careful consideration on appropriate installation location, accessories, connection method and transmitter model.

Tubing and Accessories

The most straightforward approach is to utilize tubing and fittings that cool the process medium before it reaches the transmitter's sensor. This allows for the use of standard and often more economical transmitter models. The principle relies on dissipating heat through extended piping or contained volumes.

Impulse Tubing or Syphon: Instead of mounting the transmitter directly to the process connection, it is attached via a length of impulse line. As the hot medium travels through the tube network, it loses some heat along the way to surrounding atmosphere. Syphon (also known as pigtail) is a circular metal tube installed between the process connection and the transmitter. It is designed to cool down the medium inside as well as reduce the effect of rapid pressure surge, that is more efficient and space-saving compared to arranging long impulse tubing.

Valves and Manifolds: The manifolds are another common fittings applied between process and instrument for isolation, venting and balancing. In addition to its primary jobs, the valve assembly and connecting tube are also able to dissipate a small amount of heat to the environment through thermal conduction and natural convection.

The combined use of tubing and assemblies can reduce the medium temperature reaching the process connection to a certain extent. If it can be controlled within the ambient range, this method represents an economical and ideal solution, as standard transmitters can be directly applied. However, if the medium temperature is excessively high and exceeds its cooling capacity, alternative high-temperature solutions must be considered.

High-Temperature Transmitter Models

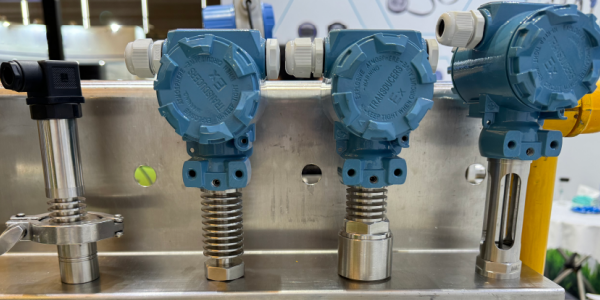

When cooling accessories are impractical or space is limited, transmitters specifically designed for high-temperature service are another option. They are not merely standard units with a higher rating, but incorporate physical and material adaptations.

Integrated Heat Sinks: The obvious feature is multiple enlarged, finned heat sinks attached between the process connection and electronics housing. These fins dramatically increase the surface area, actively radiating heat away before reaching critical sensing component and module. This design can effectively lower the temperature at the sensor and electronics.

High-Temperature Rated Components: These transmitters use semiconductors, gaskets, and internal filling fluids specifically formulated for long-term stability at elevated temperatures. Internal lead holes are filled with high-efficiency thermal insulation material, effectively preventing heat conduction and ensuring the amplification and conversion circuit operates within permissible temperature limits.

Remote Seal System

For the most challenging applications—involving very high temperatures, corrosive media, viscous fluids, or processes where solidification in impulse lines is a risk—the remote seal system is the preferred and essential choice. This method can completely remove the pressure transmitter from hot process environment.

The system consists of remote diaphragm seal, capillary tube of set length, and the transmitter itself. The entire system—seal, capillary, and transmitter sensor—is prefilled with stable, incompressible fill fluid (e.g., high-temperature silicone oil).

Process pressure deflects the remote diaphragm. This deflection is transmitted hydraulically through the thermally stable fill fluid inside the capillary to the receiving diaphragm in the transmitter, which is mounted in a safe, cool location, possibly meters away from the actual measurement point. The transmitter body never contacts the hot process medium.

Measuring pressure in high-temperature processes is a routine but critical challenge in industrial automation. The optimal protection strategy depends on a holistic analysis of the application. By employing cooling accessories, selecting purpose-built high-temperature transmitters, or implementing remote seal systems, engineers can ensure their pressure instrumentation delivers lasting accuracy and reliability. Shanghai Wangyuan is a high-tech manufacturing enterprise with over 20 years of experience, specializing in the production and service of pressure measurement instruments. We possess extensive expertise in handling high-temperature field process control solutions, backed by numerous practical case studies. Should you have any requirements or questions regarding transmitter selection for high-temperature applications, please feel free to contact us at any time.

Post time: Dec-12-2025