Kuzinhlelo zenqubo, uxhumo oluluchungechunge luyizici ezibalulekile zemishini ezisetshenziselwa ukujoyina amadivayisi aphatha uketshezi noma ukudluliswa kwegesi. Lokhu kufakwa kufaka ama-grooves e-helical enziwe ngomshini endaweni yangaphandle (yeduna) noma yangaphakathi (yowesifazane), evumela ukuxhumana okuvikelekile nokungavuzi. Lapho ihlanganiswa, imicu yenza isibopho esiqinile esikwazi ukumelana nezingcindezi zokusebenza ezihlukahlukene.

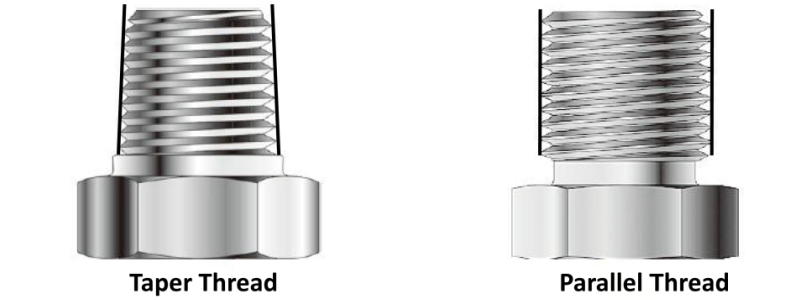

Ukuxhumana okunemicu akusebenzi nje kuphela ukubamba izingxenye ndawonye kodwa futhi nokuvimbela ukuvuza kwemidiya. Kunezinhlobo ezimbili zezintambo eziyinhloko: izintambo ezihambisanayo kanye ne-taper. Ngayinye ihlukile nge-geometry kanye nendlela yokuvala uphawu.

I-Parallel Thread

Eyaziwa nangokuthi intambo eqondile, intambo ehambisanayo inobubanzi obungaguquki kanye nephrofayili yentambo kubo bonke ubude bayo. Lo mumo ofanayo wenza kube lula ukuqondanisa nokufaka. Kodwa-ke, njengoba intambo inganciphisi, ayenzi ngokwemvelo uphawu ngokusebenzisa ukucindezela kwe-radial. Esikhundleni salokho, kungase kuncike ezintweni ezisizayo zokuvala—njenge-O-ring, i-gasket, noma iwasha—ukuvimbela ukuvuza ekufakweni kwengcindezi ephezulu. Umsebenzi oyinhloko wentambo ukunikeza amandla omshini. Lo mklamo wenza intambo ehambisanayo ifaneleke kahle ezinsizeni ezidinga ukuhlangana njalo nokuhlakazwa, njengoba uphawu olushintshwayo lwenza kube lula ukugcinwa ngaphandle kokulimaza intambo.

I-Taper Thread

Intambo ye-taper yenziwe ngomshini wokunciphisa kancane kancane ububanzi, okwenza ifomu le-conical. Njengoba izingxenye zabesilisa nabesifazane zihlanganyela, i-taper ikhiqiza umphumela wokushada okwandisa ukuthintana kwentambo futhi idale ukulingana kokuphazamiseka kwemishini. Lokhu kucindezelwa kwe-radial kwakha uphawu lwensimbi-kuya-metal, oluba luqina ngaphansi kwengcindezi, okwenza intambo ye-taper isebenze kakhulu kumasistimu anengcindezi ephezulu noma aguquguqukayo afaka amagesi noma uketshezi. Ukusebenza kokuvala intambo ye-taper kuyathuthuka ngokuqiniswa nokwenyuka kwengcindezi, okuqeda isidingo sezimpawu ezengeziwe ezinhlelweni eziningi.

Ukucabangela Ukukhetha

Izintambo ezihambisanayo zivame ukuthandwa ezinhlelweni ezinengcindezi ephansi noma lapho ukumodelisa kanye nokulungisa kalula kubekwa phambili. Kubalulekile ukukhetha ama-gasket ahambisanayo noma ama-O-rings ukuze kuqinisekiswe ukuvuza.

Izintambo ze-taper zihamba phambili ezindaweni ezinengcindezi ephezulu, ikakhulukazi kumasistimu oketshezi, umoya, noma uketshezi olucutshungulwayo. Ikhono labo lokuzivala ngaphansi kwengcindezi libenza babe ukukhetha okuthembekile ngaphansi kwezimo ezinzima.

Ukufakwa kwezinsimbi, izindinganiso zochungechunge ezivamile zihlanganisa i-Metric ne-BSPP (i-parallel), kanye ne-NPT ne-BSPT (i-tapered). Lapho ukhetha uhlobo lokuxhuma, kubalulekile ukucabangela izimo zokusebenza, amazinga okucindezela, nokuhambisana nezixhumi ezibonakalayo zesistimu. Ngesipiliyoni seminyaka engaphezu kwengu-20 ekukhiqizeni amathuluzi okulinganisa,Shanghai Wangyuaninikeza izinhlobonhlobo zezinketho zochungechunge zama-transmitters futhi isekela ukucushwa kwangokwezifiso kokuxhumeka kwenqubo. Sicela uzizwe ukhululekile ukusithinta ukuze uthole olunye ulwazi noma izidingo ezithile.

Isikhathi sokuthumela: Sep-09-2025