Ezinqubweni zezimboni ezifana nokukhiqizwa kukagesi, ukukhiqizwa kwamakhemikhali, ukuhluzwa kukawoyela, kanye ne-metallurgy, ukulinganisa ngokunembile ingcindezi ezindaweni ezishisa kakhulu kungaba umsebenzi obalulekile kodwa oyinselele. Lapho izinga lokushisa eliphakathi nenqubo likhuphuka ngaphezu kuka-80℃, ama-transmitter ajwayelekile angaba sengozini. Ukuchayeka ngqo ekushiseni okunjalo kungonakalisa izingxenye ze-elekthronikhi, kubangele ukukhukhuleka kokulinganisa, kulimaze uketshezi lokugcwalisa lwangaphakathi, futhi ekugcineni kuholele ekungasebenzi kahle okukhulu kwethuluzi. Impumelelo kulezi zinhlelo zokusebenza ezidinga amandla incike isu eliphelele elihlanganisa ukucatshangelwa ngokucophelela endaweni efanele yokufaka, izesekeli, indlela yokuxhuma kanye nemodeli yama-transmitter.

Amapayipi Nezinsiza

Indlela elula kakhulu ukusebenzisa amapayipi kanye nezinto zokufaka ezipholisa i-process medium ngaphambi kokuba ifinyelele inzwa ye-transmitter. Lokhu kuvumela ukusetshenziswa kwamamodeli e-transmitter ajwayelekile futhi avame ukuba angabizi kakhulu. Isimiso sincike ekuqedeni ukushisa ngokusebenzisa amapayipi anwetshiwe noma amavolumu aqukethwe.

Ipayipi Lokushukuma noma i-Syphon: Esikhundleni sokufaka i-transmitter ngqo ekuxhumekeni kwenqubo, inamathiselwa ngomugqa wokucindezela ubude. Njengoba i-hot medium ihamba ngenethiwekhi yepayipi, ilahlekelwa ukushisa okuthile endleleni eya emoyeni ozungezile. I-Syphon (eyaziwa nangokuthi i-pigtail) iyipayipi lensimbi eliyindilinga elifakwe phakathi kokuxhumeka kwenqubo kanye ne-transmitter. Yenzelwe ukupholisa i-medium ngaphakathi kanye nokunciphisa umphumela wokwanda kwengcindezi okusheshayo, okusebenza kahle kakhulu futhi konga isikhala uma kuqhathaniswa nokuhlela ipayipi elide le-impulse.

Amavalvu kanye nama-Manifold: Ama-manifolds angenye yezinto ezivamile ezisetshenziswa phakathi kwenqubo nethuluzi lokuhlukanisa, ukungenisa umoya kanye nokulinganisela. Ngaphezu kwemisebenzi yalo eyinhloko, ukuhlanganiswa kwevalvu kanye nethubhu yokuxhuma nakho kuyakwazi ukusabalalisa ukushisa okuncane endaweni ezungezile ngokuqhutshwa kokushisa kanye nokudluliselwa kwemvelo.

Ukusetshenziswa okuhlangene kwamapayipi kanye nezinhlangano kunganciphisa izinga lokushisa eliphakathi nendawo elifinyelela uxhumano lwenqubo ngezinga elithile. Uma lingalawulwa ngaphakathi kwebanga le-ambient, le ndlela imelela ikhambi elingabizi nelifanele, njengobaama-transmitter ajwayelekileingasetshenziswa ngqo. Kodwa-ke, uma izinga lokushisa eliphakathi liphezulu kakhulu futhi lidlula umthamo walo wokupholisa, ezinye izixazululo zokushisa okuphezulu kumele zicatshangelwe.

Amamodeli Okudlulisa Okushisa Okuphezulu

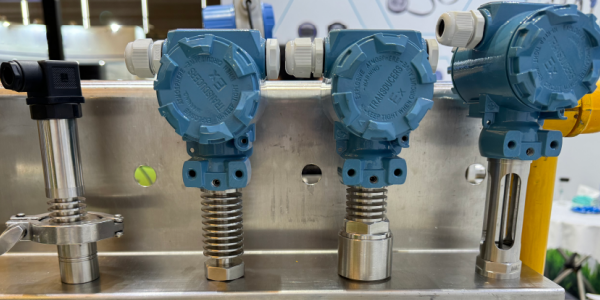

Uma izesekeli zokupholisa zingasebenzi noma isikhala silinganiselwe,abathumeliOkuklanyelwe ngqo isevisi yokushisa okuphezulu kungenye indlela. Akuzona nje amayunithi ajwayelekile anesilinganiso esiphezulu, kodwa afaka ukulungiswa okungokwenyama nokuphathekayo.

Amasinki Okushisa Ahlanganisiwe:Isici esisobala ama-heat sink amaningi akhulisiwe, afakwe amafindo axhunywe phakathi kokuxhumeka kwenqubo kanye nendlu ye-elekthronikhi. Lawa mafindo akhulisa kakhulu indawo engaphezulu, ekhipha ukushisa ngaphambi kokufinyelela engxenyeni yokuzwa okubucayi kanye nemodyuli. Lo mklamo unganciphisa ngempumelelo izinga lokushisa ku-sensor kanye ne-elekthronikhi.

Izingxenye Ezilinganiselwe Izinga Lokushisa Eliphezulu:Laba bathumeli basebenzisa ama-semiconductor, ama-gasket, kanye noketshezi lokugcwalisa lwangaphakathi olwenzelwe ngqo ukuzinza isikhathi eside emazingeni okushisa aphezulu. Izimbobo zangaphakathi ze-lead zigcwele izinto zokuvikela ukushisa ezisebenza kahle kakhulu, okuvimbela ngempumelelo ukuqhutshwa kokushisa nokuqinisekisa ukuthi isekethe yokukhulisa nokuguqula isebenza ngaphakathi kwemikhawulo yokushisa evunyelwe.

Uhlelo Lokuvala Olukude

Ngezicelo eziyinselele kakhulu—ezihilela amazinga okushisa aphezulu kakhulu, imithombo ebolile, uketshezi olunamathelayo, noma izinqubo lapho ukuqina kwemigqa ye-impulse kuyingozi—uhlelo lokuvala olukudekuyindlela ekhethwayo nebalulekile. Le ndlela ingasusa ngokuphelele isithumeli sokucindezela endaweni eshisayo yenqubo.

Uhlelo luqukethe isivalo se-diaphragm esikude, ishubhu le-capillary elinobude obuhleliwe, kanye nesithumeli uqobo. Lonke uhlelo—isivalo, i-capillary, kanye ne-transmitter sensor—lugcwaliswe kusengaphambili ngoketshezi lokugcwalisa oluzinzile nolungacindezeleki (isb., uwoyela we-silicone oshisa kakhulu).

Ukucindezela kwenqubo kususa i-diaphragm ekude. Lokhu kuphambuka kudluliselwa ngamandla kagesi ngoketshezi olugcwala oluzinzile ngaphakathi kwe-capillary kuya ku-diaphragm etholayo ku-transmitter, efakwe endaweni ephephile, epholile, mhlawumbe ngamamitha ukusuka endaweni yokulinganisa yangempela. Umzimba we-transmitter awukaze uxhumane ne-hot process medium.

Ukulinganisa ingcindezi ezinqubweni zokushisa okuphezulu kuyinselele evamile kodwa ebalulekile ezenzakalelayo zezimboni. Isu lokuvikela elifanele lincike ekuhlaziyweni okuphelele kohlelo lokusebenza. Ngokusebenzisa izesekeli zokupholisa, ukukhetha ama-transmitter asezingeni eliphezulu akhelwe ngenhloso, noma ukusebenzisa izinhlelo zokuvala ezikude, onjiniyela bangaqinisekisa ukuthi amathuluzi abo okucindezela aletha ukunemba nokuthembeka okuhlala njalo.Shanghai Wangyuaniyibhizinisi lokukhiqiza lobuchwepheshe obuphezulu elineminyaka engaphezu kwengu-20 yesipiliyoni, eligxile ekukhiqizeni nasekusesheni amathuluzi okulinganisa ingcindezi. Sinolwazi olubanzi ekusingatheni izixazululo zokulawula inqubo yensimu yokushisa okuphezulu, ezisekelwa yizifundo eziningi ezisebenzayo. Uma unezidingo noma imibuzo mayelana nokukhethwa kokudlulisela izinhlelo zokusebenza zokushisa okuphezulu, sicela ukhululeke ukuxhumana nathi nganoma yisiphi isikhathi.

Isikhathi sokuthunyelwe: Disemba 12-2025