Diaphragm hatimi da aka sani ga muhimmanci bangaren ga aiwatar iko na'urorin bauta a matsayin m keɓe tsarin ga ji abubuwa na gauges, na'urori masu auna firikwensin da watsawa da matsananci tsari yanayi-lalata sunadarai, danko ruwa ruwa, ko matsananci yanayin zafi, da dai sauransu The zabi na diaphragm tsarin hinges a kan aiki yanayi da kuma nema functionalities na aunawa na'urar da kuma akwai ma mahara hawa dangane da diaphragm hanyoyin da diaphragm hanyoyin sadarwa diaphragm.

Dangane da nisa tsakanin jikin kayan aiki don aiwatar da wurin bugun, ana iya rarraba hanyoyin shigarsa azaman shigarwa kai tsaye da shigarwa mai nisa:

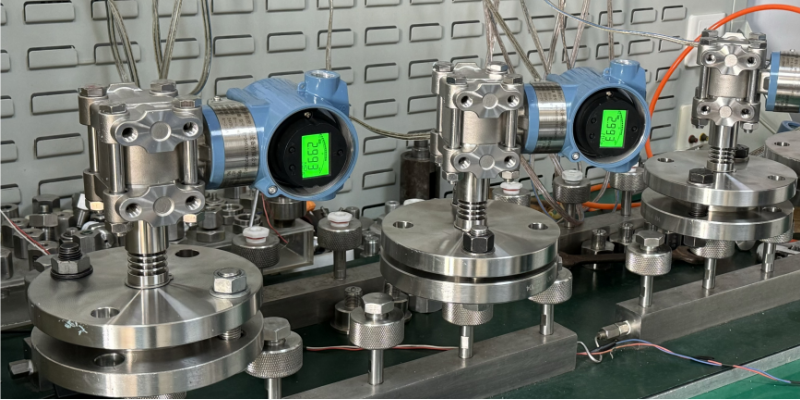

Shigarwa Kai tsaye:Hanya mai sauƙi na haɗa diaphragm kai tsaye akan tsari wanda aka haɗe tare da babban kayan aiki kuma ya kafa haɗin haɗin gwiwa. Haɗin kai tsaye ya dace da matsakaici da kwanciyar hankali. Abun ji yana aiki kusa da tsarin kuma yana tabbatar da lokacin amsawa cikin sauri da azanci akan ƙaramin canji na tsari. Masana'antu kamar maganin ruwa ko masana'antu na gaba ɗaya galibi suna fifita wannan hanya mai inganci mai sauƙin ƙira. Koyaya, hanyar ba ta dace da matsananciyar zafin jiki ko girgiza mai ƙarfi ba, saboda babban kayan aikin ya kasance a cikin kusancin yanayin yanayi mara kyau.

Shigarwa Daga Nisa:Saitin nesa yana da fa'ida lokacin da kayan aikin dole ne a sanya shi daga yanayin aiki mai tsauri ba zai iya jurewa ba - matsanancin zafin jiki, yanayi mai haɗari ko girgizar inji. A cikin yanayin an cire hatimin diaphragm daga jiki ta amfani da capillary mai sassauƙa. Cike ruwa a cikin capillary na iya aika matsa lamba da aka tilasta akan diaphragm zuwa firikwensin da ke a nesa. Tsawon capillary da zaɓin tushen cika ruwa akan dacewa da yanayin zafi da shimfidar tsari. Hawan nesa na Capillary yana haɓaka ingantaccen aiki da amincin na'urar a cikin mafi ƙalubale yanayi, haɗari da manyan zafin jiki tsakanin filayen kamar mai & iskar gas da sarrafa sinadarai galibi sun fi son hawan nesa don sarrafa tsari.

Dangane da dacewa da haɗawa, hawan hatimin diaphragm yana da haɗe-haɗe guda uku:

Haɗin zaren:Ƙananan diamita lebur diaphragm ya dace da madaidaiciyar zaren hawa (G, NPT, Metric, da sauransu). Yana da jituwa ko'ina da farashi-tasiri tsakanin aikace-aikacen matsa lamba na gabaɗaya-zuwa-matsakaici kuma yana ba da damar sauƙi mai sauƙi a cikin m wurare. Koyaya haɗin zaren bazai iya jure babban jijjiga ko zafi ba tare da ƙarin tallafi ba.

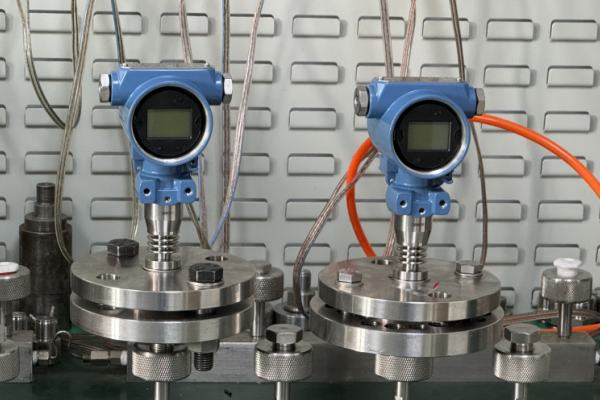

Haɗin flange:Flange yana haɗa hatimin diaphragm zuwa flange kuma yana tabbatar da babban matakin haɗin gwiwa tare da bututun sarrafawa ko jirgin ruwa, gama gari a cikin babban matsi ko tsarin diamita mai girma. Hatimin yana haɗawa tare da daidaitattun flanges (ANSI, ASME, JIS ko GB/T, da sauransu), galibi ta amfani da haɗin haɗin gwiwa don ƙarfi. Weld-wuyansa, zamewa-on, ko threaded flanges an zaba bisa ga matsa lamba ratings da shigarwa yanayin.Flange tabbatar yayyo-m yi a cikin bukatar yanayi da ya kamata a sani cewa dace flange jeri da jeri na gasket ne da muhimmanci ga yayyo rigakafin.

Haɗin haɗi: A bangaren abinci, magunguna, da fasahar kere-kere, hawan tsafta yana tabbatar da bin ka'idojin tsafta. Hatimin diaphragm ta amfani da kayan aiki mai tsafta an tsara su don sauƙin tsaftacewa da haifuwa. Santsi, saman da ba shi da fa'ida yana hana haɓakar ƙwayoyin cuta, yayin da kayan kamar 316L bakin karfe suna tsayayya da lalata. Yayin da ke nuna saurin shigarwa da ingantaccen kulawar gurɓatawa, ya kamata a lura cewa matsi bazai dace da aikace-aikacen matsa lamba ba.

Kowace hanyar hawan hatimin diaphragm na iya ba da fa'idodi na musamman waɗanda suka dace da takamaiman buƙatun masana'antu. Ta hanyar a hankali kimanta buƙatun tsari da abubuwan muhalli, injiniyoyi na iya haɓaka shigarwa don aminci, aminci, da ƙimar farashi. Zaɓin da ya dace da shigarwa ba kawai yana ƙara rayuwa mai amfani samfurin ba har ma yana tabbatar da ingantaccen sarrafa tsari a cikin aikace-aikace daban-daban.Shanghai Wangyuanƙwararren ƙwararren ƙwararren ƙwararren ƙwararren kayan aiki ne wanda yake da ƙwarewa sosai a cikin amfani da kayan aikin da aka rufe diaphragm. Idan kuna da wasu tambayoyi ko buƙatu game da kewayon hanyoyin magance mu, da fatan za ku yi shakka a tuntuɓi.

Lokacin aikawa: Mayu-09-2025